My Savannah has taken a bit of a back seat for the past few weeks what with the work I’ve had to do involving 28AAD, my Weedhopper and the weather, which has made it impossible to even get it out of the hangar. But today I went to Malbec with two jobs in mind – the first was to see about putting Malbec’s new windsock up that arrived today via la Poste and the second was to take some more measurements for my revised-revised design for the Savannah’s new towbar.

We haven’t had much more rain in the past 24 hours or so and the afternoon was dullish but warm, so the situation looked good when I arrived and opened up the hangar in an attempt to get some air circulating through it. There wasn’t much chance of that though, even with the main doors wide open because there was practically no wind to speak of.

The first thing I found was that the only ladder that I could find at Malbec was too short to get up to the windsock, so I had to abandon the idea of putting the new one up for today. That allowed me therefore to concentrate on just the Savannah.

There was absolutely no chance of getting it out of the hangar, though, because the area in front of the opening through which it would have to be brought was beyond swamp-like with water rising to the surface when even the lightest pressure was applied to it, as the following picture of my boot shows.

So then I had to raise the Savannah’s nose wheel up onto blocks to give easy access to the nose wheel for me to take the measurements that I needed.

At present the crossbar that was intended for my original towbar design is still attached to the nose wheel fork.

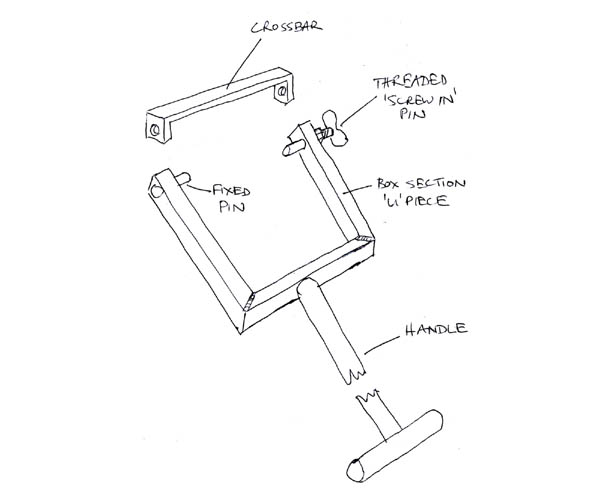

This was to be a simple ‘T’ design with a pin at each end of the ‘T’ to drop into the two holes at each end of the crossbar. The pins were to have holes drilled in them through which securing pins would have been located to ensure that the towing pins could not come out of the holes, allowing the aircraft to be pulled or pushed in safety.

There was, however, one flaw in the design. If during manoeuvering of the aircraft using the towbar it was necessary to stop and drop the towbar for any reason eg to move an object out of the way, the towbar handle would have immediately fouled the nosewheel mudguard with the potential of causing considerable damage especially if, for example, the towbar was to slip out of one’s hands while in use. There was obviously, therefore, a need to re-think the design before moving forward.

The first modification was to turn the ends of the crossbar either up or down so the holes into which the pins will locate are horizontal. This will allow the pins to act as pivots, allowing for the handle to be raised or lowered as desired in use.

But this still wouldn’t solve the mudguard fouling problem, and the only way to do that would be for the end of the towbar that connects to the nose wheel to be in a ‘U’ shape so when the towbar is lowered, the sides of the ‘U’ clear it.

The final requirement will be for the ‘U’ to be rigid enough steer the aircraft while it is being towed or pushed without bending or flexing, and the best way to achieve that would be by fabricating that part of the towbar from steel box section.

The following rather scrappy diagram shows what I’m talking about.

So taking measurements for this new, revised towbar design was this afternoon’s task and that only took half an hour or so. And then having the hangar main doors open provided just the opportunity that I needed to give the Savannah’s engine a much needed run.

I ran the engine for 10 minutes or so until its water temperature got to around 75/80 degrees before calling it a day. Now I’ve got to redo my towbar diagram with dimensions to give to my local contact who will be making it up for me. I think he’ll get a bit of a surprise because every time we speak it gets a little bit more complicated. I think that the price he gave me will also be a little bit more too 😉