Or to nobble the Hobbs. I’ll explain. Almost every aircraft, including most ultralights and ULMs, have a gauge or metre on their instrument panel for recording and displaying time. It’s widely referred to as a Hobbs gauge.

But as in many things to do with aviation, measuring time isn’t as simple as it might seem. The reason is that there are several ways in which time is significant, the most important ones being engine and airframe time and in particular the time schedules between maintenance tasks and overhauls and the ‘life’ left in components and the airframe itself.

The first one is ‘switch on to switch off’. This refers to when the master key switch is turned on to the time it’s turned off and the aircraft’s Hobbs meter that displays hours would be connected directly to the master switch in order to show it. But it’s clearly not a very relevant measure. Just because you’ve turned the power on it doesn’t mean that anything is being used, consumed or subject to wear.

If a pilot needs to switch the cabin light on to read his navigation notes there’s no reason why time should be removed from the life of the engine or airframe while he does so. Similarly, if an engineer is installing or testing the strobe light system and needs an hour or so of electrical power for that, it has no effect on engine life and there’s no reason therefore, why it should be logged.

The next time measurement is ‘engine on to engine off’.Clearly this is much more relevant to engine life and worthy of being recorded but even so, it may not represent the whole story as I’ll go on to discuss below.

Then there’s ‘brakes on to brakes off’ and ‘wheels up to wheels down’, both measures which are relevant to flight time and ‘cycles’. Most general aviation pilots use the former for logging their flight time as it covers the total period during which they have taken control of the aircraft.

Some argue that ‘engine on to engine off’ is more relevant as that’s the period for which they’re in charge as captain of the aircraft during which they are technically flying. My own view is that that overstates flying time as I disagree that sitting on the apron warming up the engine for ten minutes prior to the flight is actually ‘flying’ even though technically you do ‘have control’ of the aircraft.

For many commercial pilots, especially those flying large passenger jets, ‘wheels up to wheels down’ has to be recorded as a measure of airframe ‘flight cycles’ but it’s not something that’s particularly relevant for general aviation pilots and especially private pilots of light aircraft.

But let’s look again at ‘engine on to engine off’. There has been much discussion over the years about this measure of time that continues on the aviation forums to this day. There are many who argue that it should be strictly applied when considering maintenance schedules and engine life as engines incur ‘a high level of stress and wear’ when being started from cold just as they do when cruising at higher revs while in flight.

I personally disagree with this. Today’s engine oils are specifically engineered not to drain from bearing surfaces, pistons and cylinder walls as they did in the past. Modern lubrication technology sees to that. So to argue that engines incur a high level of stress at start-up is, I believe, over-stating the case somewhat.

And I think that’s it’s also wrong to equate the ten minutes or so that a modern engine ticks over at low revs while warming up with a similar period during flight at cruise engine revs. So what’s the answer?

It seems to me that what is necessary is some compromise means of measuring time that is based on engine use but takes account of when an engine is running slowly and not subject to the stresses involved in climbing or working at cruise revs and luckily there is already something in existence that provides an engineering based solution.

This is the so-called ‘tacho reading’ or tacho time. Tachos, short for tachometer, are time recorders that are built into an engine’s rev counter and are designed to take into account engine revs. Tacho time is similar to Hobbs time but instead of measuring actual hours that the engine is running it measures engine RPMs. This means that the tacho time cycles through the numbers more slowly at idle and low throttle settings, and faster at higher power settings.

Tacho time varies according to aircraft type and is calculated based on the average cruise RPM of the aircraft in question. So in many ways, this represents the ideal way to measure time when considering maintenance schedules and engine life and in most situations in general aviation it is used for precisely that purpose.

But there is only one problem. Tachos are found in all normal general aviation aircraft from light singles upwards but are not usually found in ultralight aircraft and ULMs like my Savannah which usually have to use much cruder methods of measurement, especially in the form that they come ‘straight from the factory’.

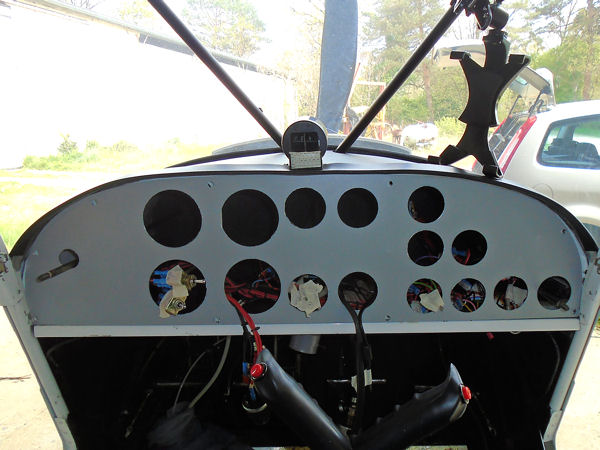

So what is my concern in all of this, you may ask? As hinted above, my Savannah does not have a tacho. In fact it has the worst of all worlds, a Hobbs gauge that’s linked to the master switch that has caught me out on more than one occasion when I’ve left it on and had hours ticking up even though the engine was not switched on.

And to make things even worse, I have been keeping a strict record of tacho v flying hours and have found that my Hobbs gauge is slightly over-reading, so I’m losing out all round as the only ‘log’ that came to me with the Savannah was an Excel spreadsheet that records only the Hobbs time.

This means that if I left things as they are, not only would I be carrying out servicing at unnecessarily frequent intervals but I’d also be losing out on the value of my aircraft when I eventually come to sell it through understating the hours left on its engine. This could be by as much as 15%, so not an insignificant figure.

So what might be the solution? My original aim was to modify the Hobbs gauge circuitry so that at the very most it only began recording when the engine was started. As mentioned previously, this can be accomplished quite simply by introducing a diode into the circuitry that only switches on when the alternator starts to generate a current.

Although more acceptable than what I have at present, I did not see this as being the optimum solution however, because the Savannah’s 912 engine has to warm up at idle revs for around ten minutes before each flight and as I said before, I do not think that this should be counted against logged time. I therefore raised a question on the microlight forum and was intrigued when Sean in the UK posted a reply.

Sean came at the problem from a different direction but essentially his objectives were similar to my own. He oversees a small fleet of Ikarus C42 microlights which are frequently hired by his club members for their own use. He has to charge by the hour but needs a form of time measurement that is not only realistic given the need to maintain the aircraft correctly in accordance with published maintenance schedules but is also fair to the members.

And he also has another concern. Because members wish to keep their hire charges to a minimum, there is a great incentive for them to minimise the time spent warming up the engine and to begin their detail as soon after starting the engine as possible. This would be good for them but ultimately terrible for the engines so Sean needed to find a way to deal with it effectively but in as fair a way as possible.

And he came up with a very elegant solution in the form of a small microprocessor controlled module that powers the Hobbs meter via a signal received from the rev counter. Ideally he would probably have liked to base his charges on tacho hours, but as microlights don’t come with tachos, his method apart from being very elegant, is clearly the next best thing.

The concept of Sean’s circuitry is relatively simple. Each aircraft’s Hobbs gauge is connected pemanently to its 12V positive electrical supply but its earth is connected and disconnected by the module. The module receives a signal from the aircraft’s rev counter and is programmed not to connect the Hobbs’s earth until a specified rev figure is attained, in his case 3200 RPM.

So after an aircraft’s engine has been started, its Hobbs gauge does not run while the engine is warming up at low revs and only starts to register when it starts to taxy. The Hobbs then continues running continuously thereafter until the engine is slowed to a specified low revs figure, in Sean’s case 500 RPM, so the members are happy as they are not charged while the engines are idling warming up and Sean’s happy because the engines are not being subjected to poor practices.

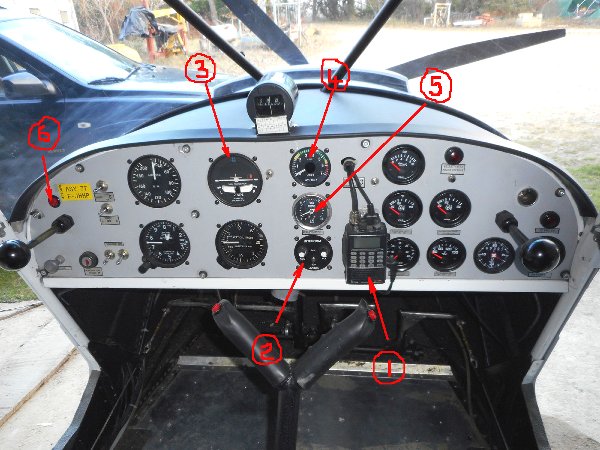

Originally I would have been content going for just the simple ‘diode in the charging circuit’ route so my Savannah’s Hobbs gauge only registered while its engine was running. However, I was so intrigued and impressed by Sean’s solution that I decided to take that route instead and over the past week or so have been busy solving the intellectual puzzle of how to convert Sean’s circuit diagram into an actual layout that I can create on copper strip circuit board.

I think that I’ve succeeded but will have to check and check again to avoid any mishaps before I begin actual soldering work. I’ve already begun receiving the components that I need, which are not expensive, including the little Arduino Pro Mini microprocessor that’s at the heart of the module. I amended Sean’s code for my Hobbs to start recording at 3200 RPM and to stop at 1600 and uploaded it into the processor today.

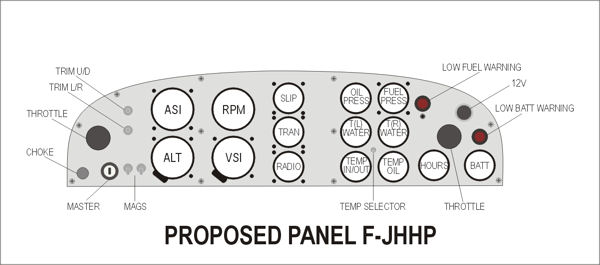

The trick will be to program the module with figures that emulate a GA aircraft’s tacho output. From my experience when I was a member of a Piper Cherokee group that charged for time using tacho hours, this was somewhere around 90% of flying time, so that will be my target. I’m now looking forward not only to completing the Savannah’s panel upgrade with its new avionics but also incorporating this neat little module into its Hobbs gauge cicuitry and I’ll let you know how I get on 😉