I’ve already mentioned that over the week-end I acquired a good used wooden propeller for 28AAD, my French Weedhopper. The prop came off an older, different version of the Weedhopper with a Rotax 532 engine and as 28AAD will have MYRO’s old 503 engine, I had to make a decision as to whether the prop would be suitable. I knew its diameter and pitch and here’s how I went about doing it.

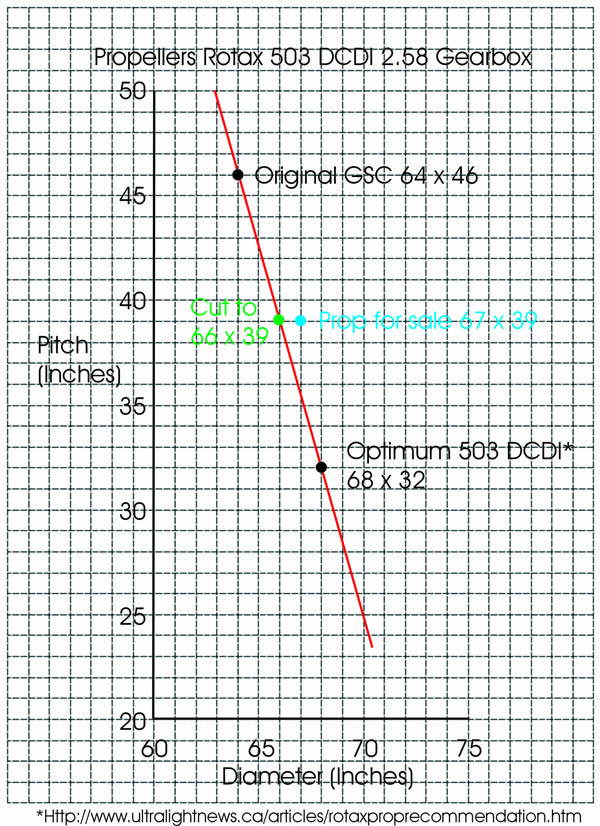

The engine is fitted with a type ‘B’ gearbox with a 2.58 ratio and here’s the data that I knew. Firstly, the original GSC wooden prop that was fitted to UK AX3s was of 64 inch diameter and 46 inch pitch and secondly, it has been established* that the optimum prop for a 503 DCDI engine is of 68 inch diameter and 32 inch pitch.

* http://www.ultralightnews.ca/articles/rotaxproprecommendation.htm

Now I’m no prop expert but I’m assuming that the GSC prop was selected as being ‘optimum’ for the engine/gearbox combination. I contend therefore that these two points can be plotted on a graph of propeller pitch v diameter and that as the distance between them is small, they can be joined by a straight line as shown in the following image.

So now we can start playing with the data for the new prop, whose data is diameter 170 cms (67 inches) and pitch 100 cms (39 inches) and is shown on the graph by the blue spot, which is off to the right of the ‘optimum’ line. The conclusion therefore as it’s off the line is that it is not optimum for this engine/gearbox combination.

Nothing can be done to modify the prop pitch as that’s inbuilt into its design, but its diameter is variable and it can be seen that if it’s reduced to 66 inches (the green spot), then the propeller falls directly onto the ‘optimum’ line.

So my conclusion is that as its stands, the new prop is not ‘optimum’ for the 503 DCDI engine/2.58 gearbox combination, but it can be made so by trimming ½” off each tip.

I’m not sure what this means in reality, however. It seems to me that the difference in diameter is so small that the change in prop performance could well be insignificant and not worth the work and effort involved. So what I intend to do is try it first as it stands and see what static revs it gives at full power. Depending on the results only then will I consider cutting it down.